learn about our history

About Us

specialist in design Engineering

Satyam

Engineering

Services

Satyam Engineering Services is a specialist design Engineering team in detailed engineering and project management consultancy, providing services to Chemical, Petrochemical Refinery, Fertilizers, Oil & Gas Projects. SES is a team of young, efficient, qualified and hardcore professionals with broad spectrum of consultancy and industrial background. The Corporation has only one operating subsidiary in the engineering field with the capability to provide services to satisfy the particular project needs of its client.

Satyam Engineering Services is able to provide qualified people in all level of experience to fulfill your requirement within time limit given by you. We can depute following professionals / Engineers / Designers / Checkers / Pds-PdmsModeler, other

technicians / Office support staff as per the requirement within the short notice.

02

Cost and Time saving in hiring process Availability of experts for short and long duration / project related work Large numbers of resumes flexibility in hiring statutory obligations such as workmen’s compensation, provident fund, gratuity, overtime, bonus, maternity benefits and professional tax are no longer a clients responsibility.

03

Health and safety is a primary concern in Satyam Engineering Services, and our excellent safety record bears witness to this fact. We firmly believe that continued emphasis on our active safety program will continue to provide a safe, healthy workplace for our personnel and those around them. Our zero-incident safety philosophy is a priority and is part of our normal business.

Our Vision

“Engineering a better future for mankind by designing safe, affordable and quality solutions.”

remember the past

Since 2011

Our office in Mumbai, provides engineering & construction services for a broad range of project types, industries serviced by SES include environmental, hydrocarbon processing, industrial power and mineral processing. An activity within the environmental sector includes waste treatment, hydrocarbon processing & petrochemical industries.

Our outlook for the process industry as a whole is one of optimism. SES has maintained its place of leadership and is well positioned to provide first rate quality engineering & construction services to clients. Our leadership experience & innovative abilities are qualities known to our clients and assure them of projects completed on time and within the budget with state of the art technology & design.

Service with a Smile

Meet Our Team

Mr. Ganesh Pawar

Mr. Narendra Patnani

Mr. Mrinmoy Ghosh Choudhary

Mr. Haridas Thandassery

Mr. Mahesh Khochare

Mr. Eshwar Pawar

Mr. Sharad Naik

Mr. D. P. KULKARNI

Mrs. Veena Gore

Mr. Abhishek Waghmare

Mr. Tushar Ajmera

Mr. Rajesh Soni

Mr. Sharad Naik

Mr. Sanjay Shelar

Mr. Haresh Kukreja

We create synergy

Associate Engineering Firms

FireTech Equipment & Systems Pvt. Ltd. (Established year 1994)

Services provides such as Fire Fighting Design & Detail Engineering, Manufacturing & supply of Fire Fighting Equipments in various ranges.

Akash Engineering Services

Offering the services in Design and Detailed Engineering, procurement & Installation, Testing, & Commissioning in chemical and Petrochemical Industry.

FABTECH Consulting & Structural Engineers

Fabtech Consulting & Structural Engineers is the professional Design and Fabrication Detailing Company with the most advanced and computerized one

S D VAIDYA Architects Pvt Ltd

Professional in Design, interior ,Exterior & Architectural layouts for Plant Bldg, office & Mosque

RP Engineers & Project Consultants Pvt Ltd

Project Management Services, Basic Engineering, Detail Engineering, Procurement Assistance Commissioning Assistance

Safety first

Health, Safety Premises

At Satyam Engineering Services, safety and health incidents are simply not acceptable. Satyam Engineering Services is committed to ensuring that working conditions are safe, workers are treated with respect and dignity, and manufacturing processes are environmentally responsible. Most companies agree they have an obligation to provide their employees with a safe and secure work environment. They create safety programs, insist on employee training and have occasional meetings. But at Satyam Engineering Services, we take safety to the next level. Our goal is to take safety to Beyond Zero by preventing even one accident from occurring. We put the personal health and safety of our employees first – wherever they are. For us, safety is more than a policy manual or a training video; it’s how we do business and it’s how we live. Our people are our greatest asset and the basis for our success. We believe that we owe it to our employees to help keep them and their families, communities, our clients and our contractors healthy and happy. When you join Satyam Engineering Services, you join a culture of caring.

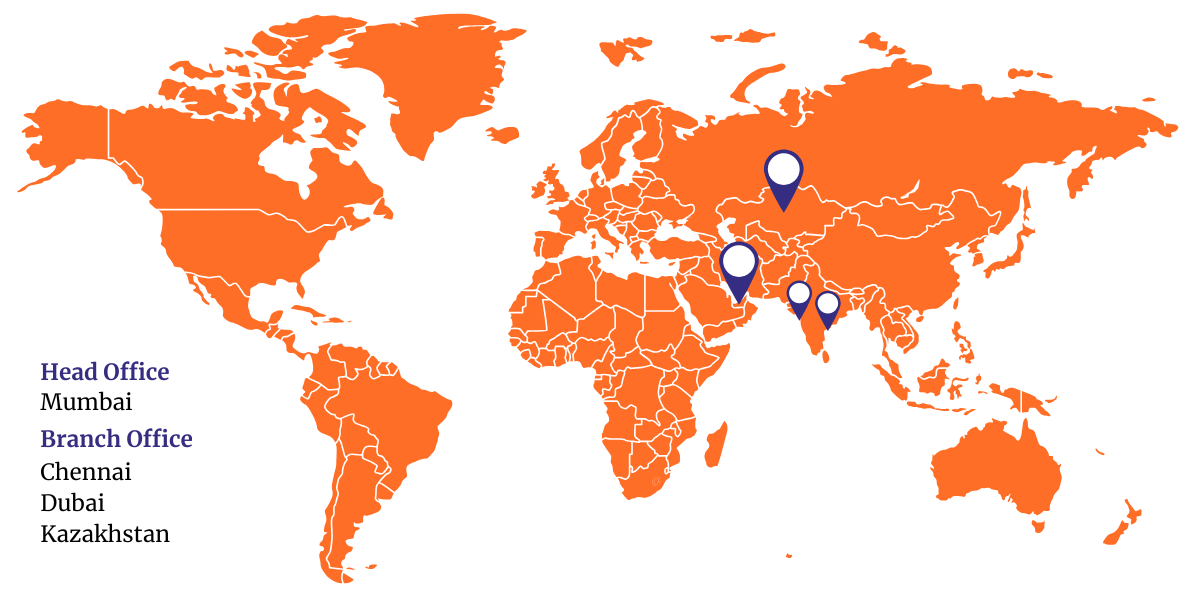

Our Branches